Domin were set the project brief of designing and testing a lightweight, high power density and high torque fixed displacement pump. The specification demanded a highly efficient, low speed (4,000 rpm) and high torque positive displacement pump.

Domin were awarded an Innovate UK funded smart project to prove the concept and went back to first principles to optimise the design of a fixed positive displacement pump with the revolutionary manufacturing technique of metal additive manufacturing.

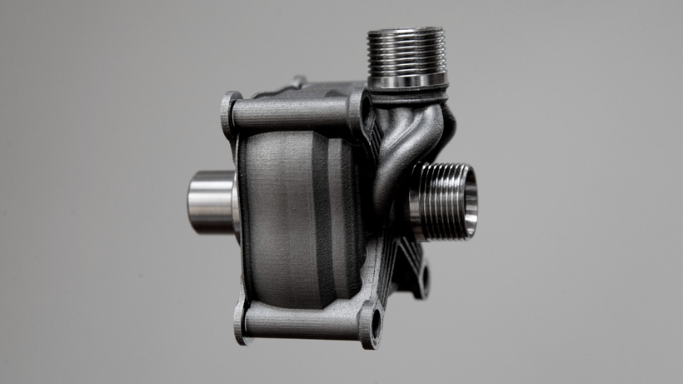

Through the combined use of high-end design software, finite element analysis software and computational fluid dynamics, Domin were able to design and make a high torque fixed displacement pump with a power density of 23 kW/kg, a torque of 40 Nm and a displacement of 14 cc/rev.

After the Innovate UK project, Domin were able to manufacture prototypes of the pump and test them as both a positive displacement pump and motor.

There is a complex set of compromises within a radial piston pump and high radial forces that need to be managed in order to be able to design an efficient pump with a reliable life. The most efficient way to do this is to have a high torque fixed displacement pump that is made up of a pintle that is pressure balanced along its length. However, in order to do this, the pintle will require a very complex hydraulic commutation that ports the inlet and outlet around the pintle and along its length.

During the last century, whilst significant work was carried out on the development of radial piston pumps, the manufacturing techniques available did not allow for this to be achieved. Metal additive manufacturing has allowed Domin to approach this problem from first principles and through the innovative application of metal additive manufacturing applied the technology to design an efficient and lightweight commutation element of the high torque fixed displacement pump.

This project has proven the innovative application of radial piston pump design through the use of metal additive manufacturing. Domin are continuing the development of this and other positive displacement pumps designed from first principles, using metal additive manufacturing as a key manufacturing and design enabler.