Intelligent Solutions

for Industrial

Our Solutions

Moving Industrial Forward

As the world moves towards electrification and sustainable movement, the use of energy and control of motion becomes ever more critical.

Our technology offers class-leading performance in a highly compact package, making it the clear choice for motion control applications across industrial manufacturing.

Next-generation design

Enabled by Ground-breaking Technology

- Ultra-compact electrical motor and pump unit.

- Sophisticated hydro-pneumatic circuit using additive manufacturing

- High-speed control of multi-function valves

- High-speed digital motor control

Setting New Standards in Power Density

and Dynamic Performance and Without Compromise

Select hotspot to see more information

Increase reliability

Get less down time with no first stage, all small blockage prone features are removed

More contamination resistance

With a more powerful motor, the high torque electric motor gives great resistance to chip shear events. Intelligent onboard electronics can detect chip shear events and shut valve to avoid damage.

Reduced Costs

Reduce maintenance cost by being fatigue proof; all valves are cycled to 5250psi for 1 million cycle pre-shipping and are designed and built to last.

Select hotspot to see more information

Select hotspot to see more information

Improved performance

Advanced electronics give precise and accurate closed-loop control and modern spool sensing technology.

Increased productivity

Fast steps responses of 3ms compared with competitors of over 8ms, high flow rates, and high frequency response.

Great Repeatability

Low hysteresis that give high accurate movement in both directions, low threshold, and low null shift.

Select hotspot to see more information

Select hotspot to see more information

Flexible

Easy to interchange these units with affordable assembly kits available to minimise system changes. These include female connectors and adaptor plates.

Lower servicing costs

With no high-pressure seals, no filters, fewer components, simpler assembly, and environmental sealing.

Energy Savings

Considerable annual energy savings with elimination of quiescent leakage from the pilot stage, reduced hydraulic power consumption, reduced CO2 consumption by 1 ton annually when replacing a two-stage with a DDV, and 1 tonne of CO2 required 2500 kWh of energy.

Select hotspot to see more information

Select hotspot to see more information

Increase reliability

Get less down time with no first stage, all small blockage prone features are removed

More contamination resistance

With a more powerful motor, the high torque electric motor gives great resistance to chip shear events. Intelligent onboard electronics can detect chip shear events and shut valve to avoid damage.

Reduced Costs

Reduce maintenance cost by being fatigue proof; all valves are cycled to 5250psi for 1 million cycle pre-shipping and are designed and built to last.

Select hotspot to see more information

Select hotspot to see more information

Improved performance

Advanced electronics give precise and accurate closed-loop control and modern spool sensing technology.

Increased productivity

Fast steps responses of 3ms compared with competitors of over 8ms, high flow rates, and high frequency response.

Great Repeatability

Low hysteresis that give high accurate movement in both directions, low threshold, and low null shift.

Select hotspot to see more information

Select hotspot to see more information

Flexible

Easy to interchange these units with affordable assembly kits available to minimise system changes. These include female connectors and adaptor plates.

Lower servicing costs

With no high-pressure seals, no filters, fewer components, simpler assembly, and environmental sealing.

Energy Savings

Considerable annual energy savings with elimination of quiescent leakage from the pilot stage, reduced hydraulic power consumption, reduced CO2 consumption by 1 ton annually when replacing a two-stage with a DDV, and 1 tonne of CO2 required 2500 kWh of energy.

Select hotspot to see more information

Increased Reliability, Performance & Profitability

More Efficiency

Reduce hydraulic power consumption.

More Power

Reduce weight by hundreds of kgs.

More Precision

Reduced waste.

More Control

Lower hysteresis.

More Speed

Less bandwidth.

More Performance

Reduced costs.

Configure and Buy your Perfect

Servo Proportional Valve

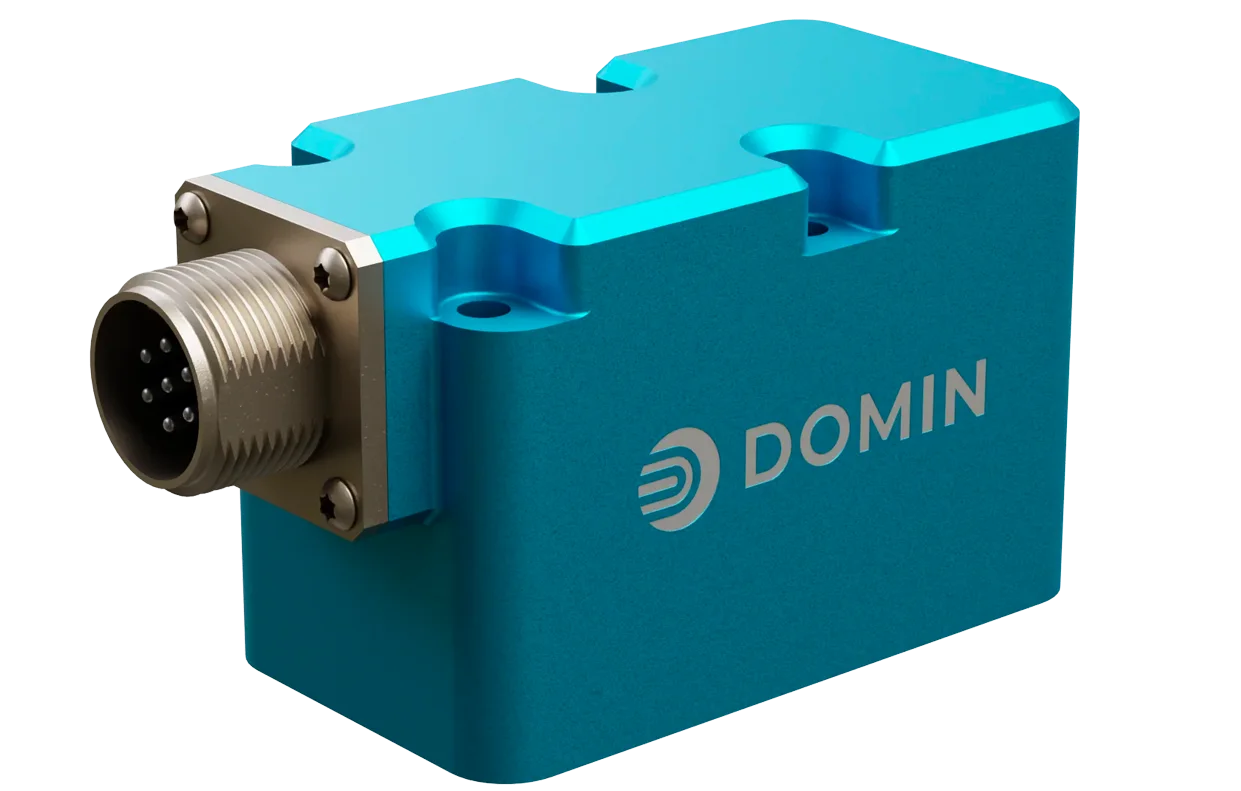

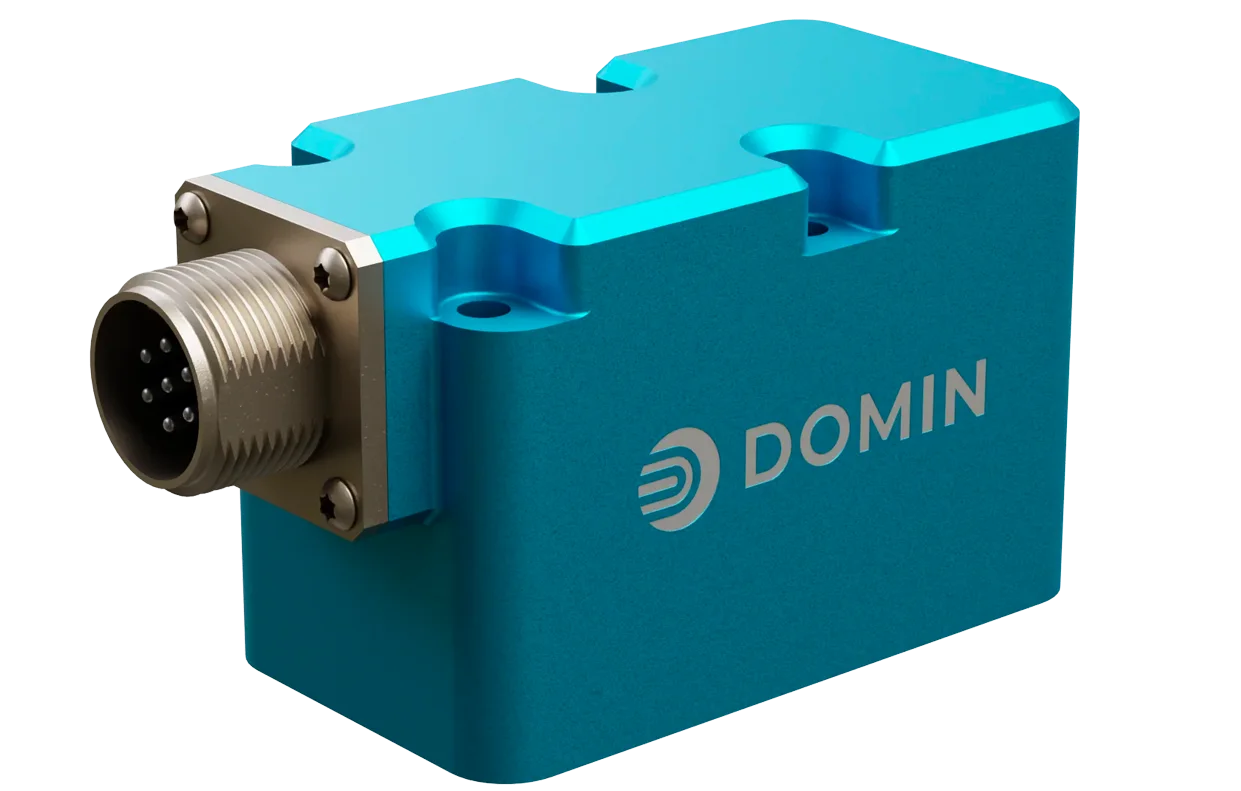

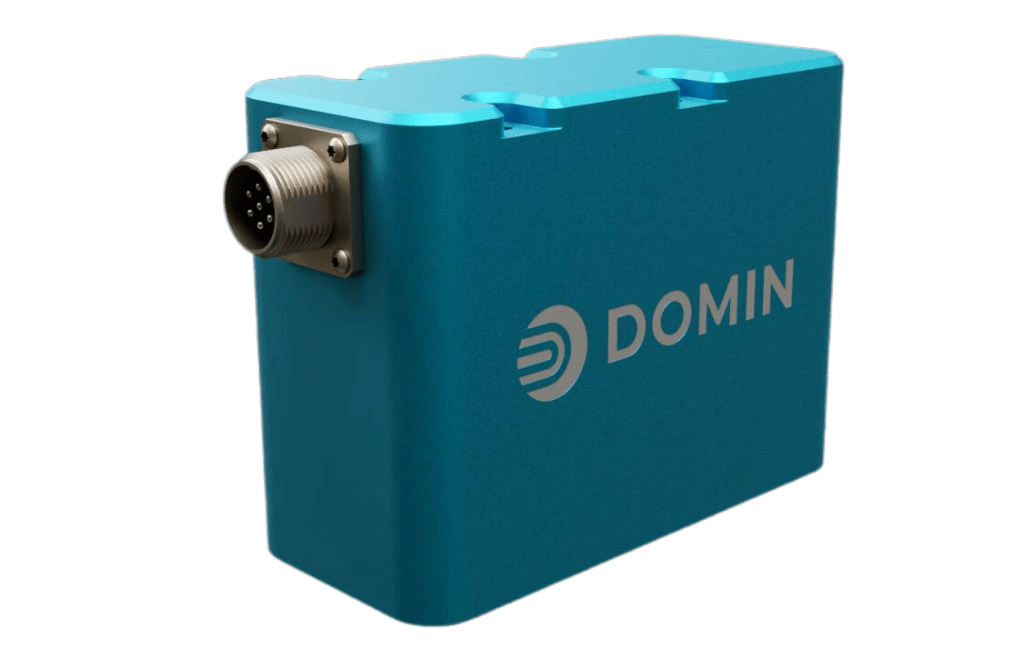

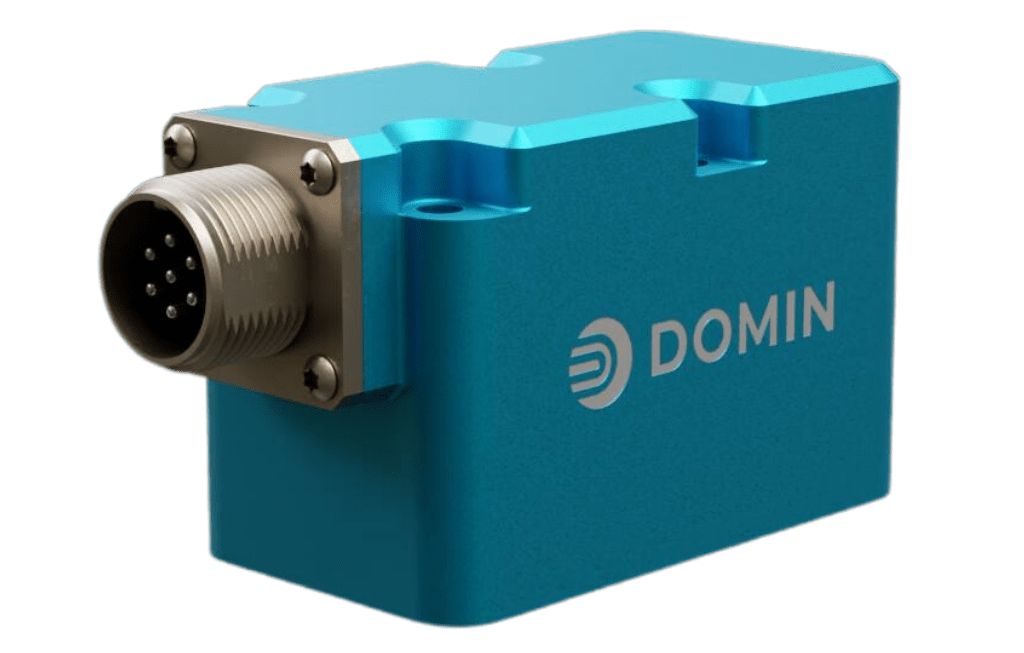

S10 Pro

The Domin S10 Pro is a single-stage servo proportional valve which combines high flow, excellent dynamics, strong chip shear, and low power consumption. The S10 Pro has been designed to sustain high bandwidth operation at exceptional flows without significant limitation of operating pressures or duty cycles.

S6 Pro X

The Domin S6 Pro X servo proportional valve builds upon the benefits of the S6 Pro. Notably, the S6 Pro X is available in two versions: voltage-controlled and current-controlled, providing greater flexibility in its application.

S6 Pro

The Domin S6 Pro servo proportional valve has been designed to achieve the best characteristics from two competing valve technologies: fluid amplified electrohydraulic valves and proportional valves.

S4 Pro

The S4 Pro valves are lightweight, high-performance directional flow control valves. Suited to applications requiring superior performance, dynamics and reliability expected of a proportional valve in an ultra-compact package.

Sales Manager, Peerless Engineering

Head of R&D, PYTHEAS Technology

Vice President, The Servo Group

Technical Manager, Careful Hydraulics and Electronics

To Give You Significant

Cost Savings

Our novel design for hydraulic systems will revolutionise the way that energy is used in industrial and commercial applications.

By reducing energy waste by 95% companies could save $400 of energy costs per year per valve, enabling significant cost savings for industrial operations.

Latest Industrial News

From Blueprint to Reality: Building Effective Hydraulic Systems

Traditional centralised hydraulic systems are heavy and inefficient. They are built with a number of different components, meaning that energy is wasted and efficiencies are throttled. At Domin, we have revolutionised the way hydraulic systems are built, making them much more efficient. In this article, we are going to explore how we build our hydraulic […]

What Are the Best Hydraulic Servo Valves for Industrial Manufacturing?

Hydraulic servo valves are commonplace in the aerospace, automotive, and industrial manufacturing industries, among others. Yet, for the most part, they still rely on decades-old, inefficient technology. This article will take a look at how Domin is challenging this, and how to choose the best hydraulic servo valves for industrial manufacturing. What Are Servo Valves? […]

Domin Make it Simple to Interchange Valves in Existing Hydraulic Systems

Hydraulic systems play a critical role in various industries, from construction and agriculture to manufacturing and aerospace. These systems rely on valves to control the flow and pressure of hydraulic fluids, ensuring smooth and efficient operation. However, as technologies advance and operational requirements change, it becomes necessary to update and replace valves in existing hydraulic […]