Electrohydrostatic vs. Electromechanical: Which one is Best?

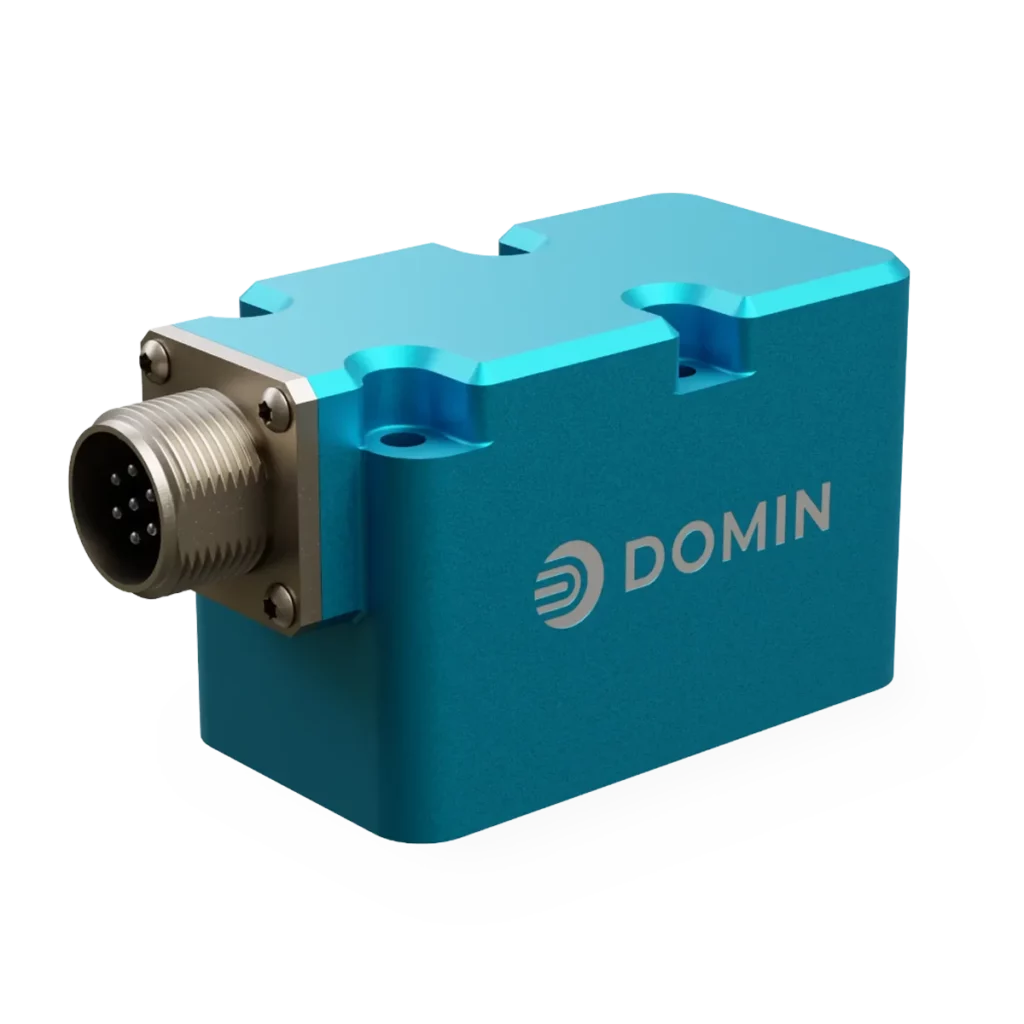

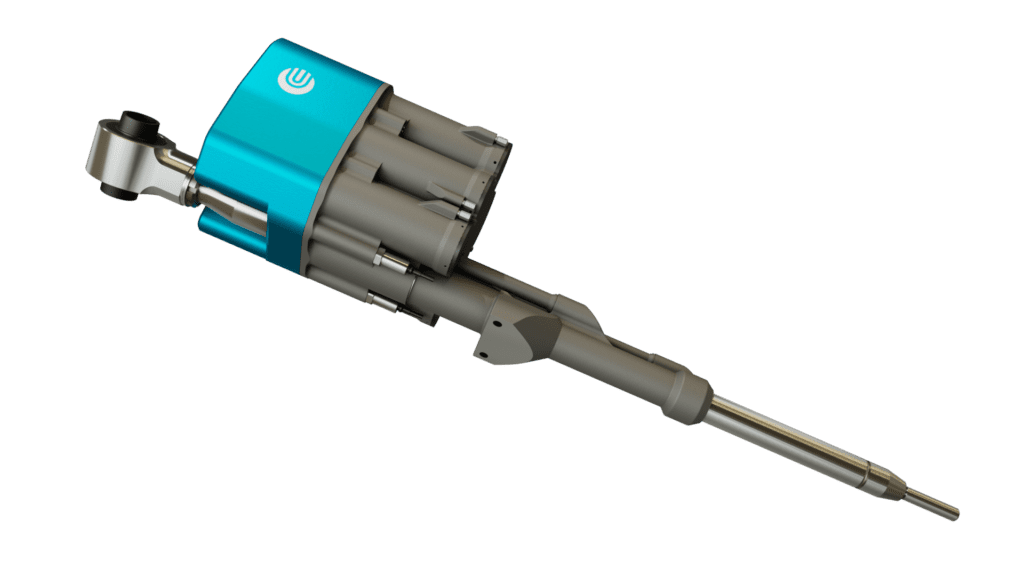

There has been a recent shift away from traditional central hydraulic systems. Electrohydrostatic and electromechanical motion control have become the two popular alternatives for controlling