Background

Delta Motion is a manufacturer of industrial automation products specialising in high performance hydraulic motion control. They offer extensive hands-on training programs and support for their customers. Importantly for Domin, Delta Motion tests a wide range of servo and proportional valves, including those from Domin’s competitors. Their test setup is designed to evaluate motion control performance in real-world customer applications, which provides different results than standard manufacturer testing focused on robustness and reliability.

Delta Motion is a well-regarded company that publishes valve test results and uses them to recommend specific valves based on customer needs. Testing Domin valves would provide Domin with additional credible third-party data from a trusted source.

Testing Overview

Delta Motion were given one each of Domin’s S4 Pro, S6 Pro, and S10 Pro valves for evaluation. The goal was to test the Domin valves to understand their levels of performance against their published specifications by the maximum amount possible.

The S6 Pro (size 06, ±10V input) and S10 Pro (size 10, ±10V input) were tested on a system with a 2 inch bore cylinder with a 24-inch stroke. The S4 Pro (size 01 ±10V input) was tested on a system with a 0.875 inch bore cylinder with a 6-inch stroke. For both systems, supply pressure was 1500 psi provided by a pump and accumulator, position sensor resolution was 1µm and the motion controller update rate was 1 ms.

The testing methodology evaluated:

• Linearity of spool position versus command signal

• Step response time

• Stability under pulsed inputs

• Frequency response

• Position control performance

• Force control performance

S4 Pro Servo Valve

Key Results

- Highly linear spool position response to input signal

- Very fast step response, estimated at 3 ms to 100%

- Maintained stability under pulsed inputs without failure.

- Held position within ±0.0003 in variation.

- Tracked velocity setpoints up to 15 in/s with 100 in/s^2 acceleration/deceleration.

- Delivered excellent force control with noise attributed to test setup limitations rather than valve performance.

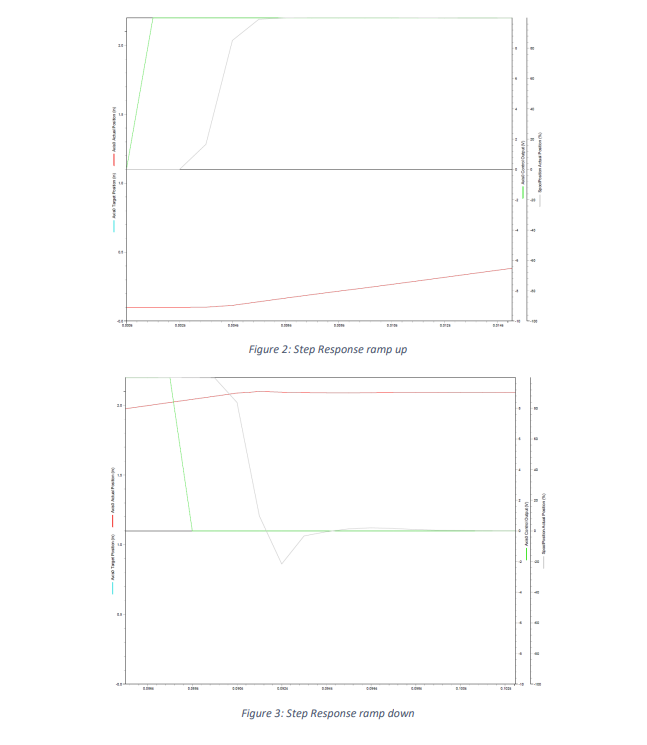

Step Response

The step response was tested by feeding the valve a step input and monitoring the spool position. Unfiltered velocity is plotted. As shown in Figure 2, the valve reached 100% within 5ms. Accounting for delays due to the 1 ms update rate, the actual step response is likely around 3ms. Figure 3 shows the movement from 100% to 0% spool position, which exhibits some overshoot.

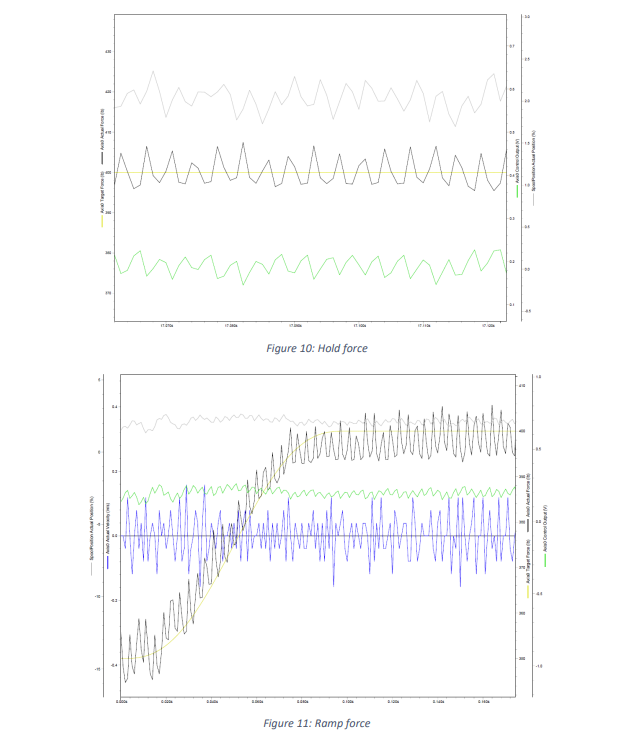

Force Control

The Domin valve was able to perform force control well. The noise in the plots is due to the system, not the valve, and did not allow the most precise analysis. From the tuning experience and control experience, the valve felt very capable of good force control.

S6 Pro Servo Valve

Key Results

- Excellent spool position linearity, with smooth response at ramp rates up to 100%

- Fast step response reaching 100% in approximately 5 ms

- Stable behaviour under pulsed inputs without loss of control

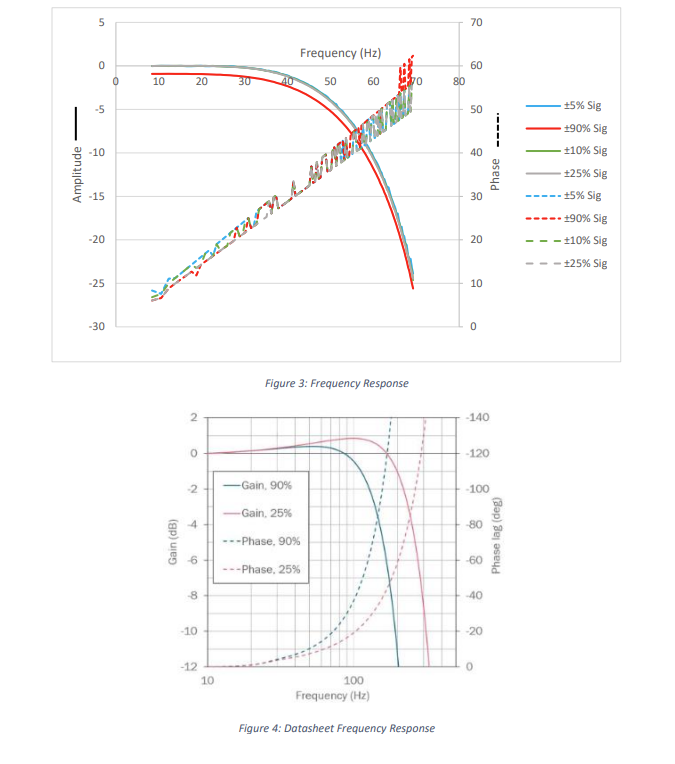

- Bandwidth of 70 Hz at ±10% amplitude variation and phase shift under 45 degrees

- Precise position control within ±0.00008 in deviation

- Accurate tracking at velocities up to 16 in/s and accelerations up to 800 in/s^2

- Smooth force control response with some minor oscillations in control output when decreasing force

Frequency Response

The frequency response was tested by outputting an open loop voltage sine wave with a varying frequency from 1 Hz to 100 Hz over 5 seconds. The spool position was monitored, and data collected every 0.250 milliseconds.

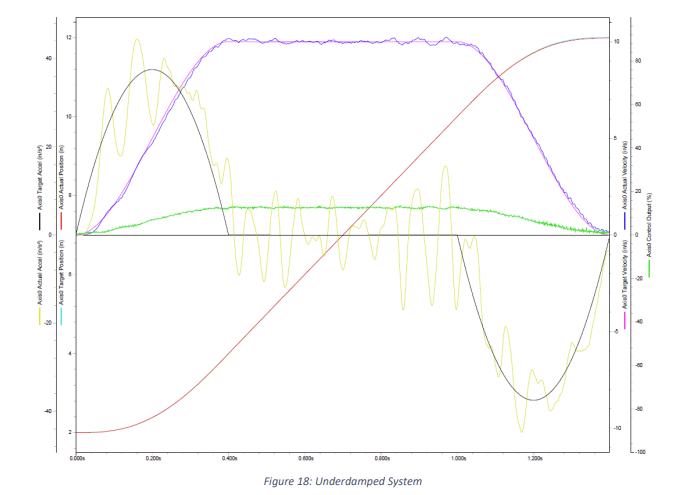

Controlling an Underdamped System

The valve was placed on a system with a very low natural frequency that requires Double Differential Gain and Jerk Feed Forward. The valve performed very well.

S10 Pro Servo Valve

Key Results

- The valve demonstrated highly linear spool position response across the full operating range when tested by ramping the input voltage from 0 to 100%.

- Fast step response was observed, with the valve reaching 100% spool position in approximately 7 ms and stabilizing within 13 ms.

- The valve maintained stability under pulsed command inputs without any oscillation or loss of control.

- Excellent position control was achieved, with the valve able to hold commanded position within ±0.00004 in variation.

- Velocity setpoints up to 15 in/s were accurately tracked with 100 in/s^2 acceleration and deceleration rates, though some minor control output oscillations were present during motion.

- Tight force regulation was observed within ±5 lbf of setpoint with minimal ±0.10% control output variation, indicating excellent force control.

- The valve demonstrated smooth tracking of force setpoints under dynamic conditions when tuned.

Position Control

Closed loop position control was tested by a technician tunning the system as good as possible. As seen in fig 8, the valve held position with minimal oscillation of ±0.00004in.

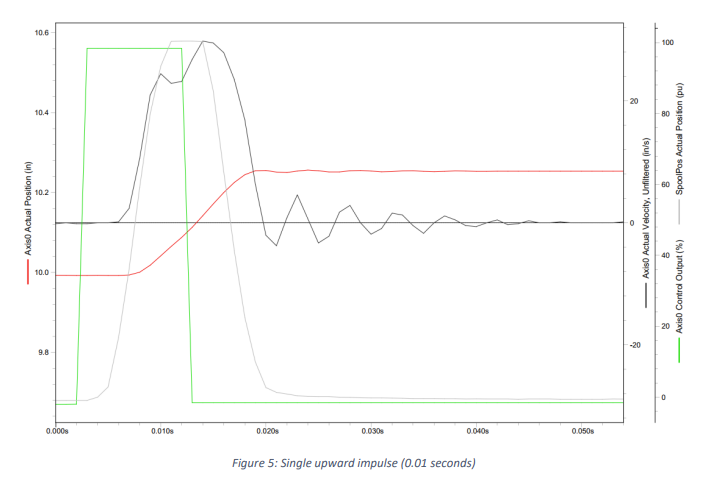

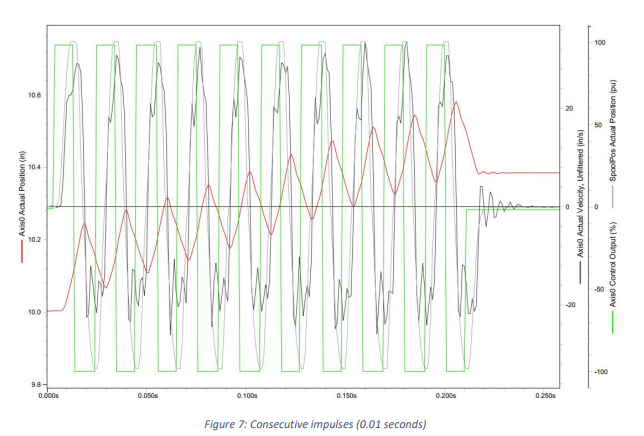

Valve Stability

Different pulses were applied to the valve to test its stability . The valve was responsive and remained stable thoughout the tests. The figures below illustrate the resulting plot from different pulses.

Conclusions

The valves demonstrated excellent motion control capabilities for position, velocity and force regulation. The results validate Domin’s claims about servo valve performance and showcase advanced technical abilities.

Across all three servo valves tested – the S6 Pro, S4 Pro, and S10 Pro – Delta Motion’s results showed:

- Highly linear spool position response to input signals

- Very fast step response times, reaching 100% in 3-7 ms

- Stable behavior under pulsed inputs without oscillation or loss of control

- Precise position control within ±0.00004-0.0008 in variation

- Accurate tracking of velocity setpoints up to 15-16 in/s with high accelerations

- Tight force regulation within ±5 lbf and low control output variation

- Overall excellent capabilities for position, velocity and force control

In summary, the testing performed by Delta Motion proves Domin’s expertise across their servo valve lineup. The S4 Pro, S6 Pro and S10 Pro all achieved exceptional performance in key areas of linearity, dynamics, stability, position accuracy, velocity tracking and force control. These results validate Domin’s capabilities and demonstrate their leadership in driving new standards for high-performance servo valves. The testing results from Delta Motion cements Domin’s reputation as an innovative player advancing servo valve technology.

Delta Motion is a US registered trademark of Delta Computer Systems, Inc. dba Delta Motion.

Partner with Domin

With extensive expertise in servo valve engineering and a proven track record of enabling success in challenging applications, we are eager to collaborate with new partners. Whether your project is in marine technology, aerospace, automotive, or beyond, let’s explore how our valves can optimise your systems. Reach out now to get started on advancing your technology for the future.