Precision Control for Diverse Applications

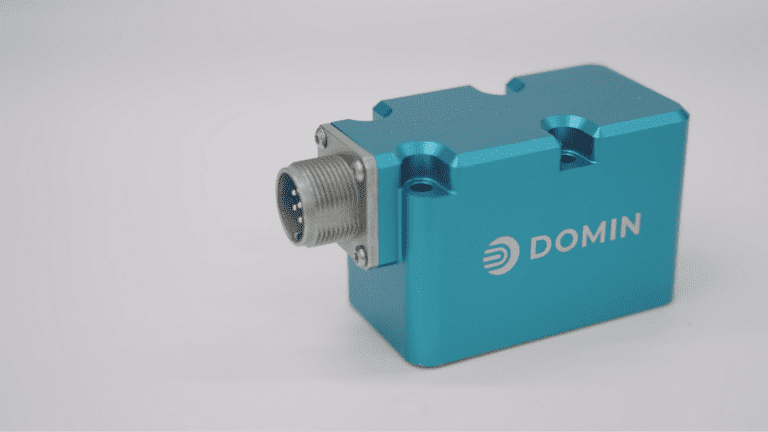

Achieving precise control, accurate motion, and short cycle times is paramount in the Test & Simulation industry. Servo valves, renowned for their exceptional fluid control capabilities, are indispensable for ensuring high-performance hydraulic actuation. Domin’s servo valves, specifically engineered for the highly dynamic demands of the test and simulation environment, stand out in delivering unmatched speed, precision, and control.

Domin’s servo valves are engineered to deliver exceptional performance in the demanding test and simulation environment. With advanced design techniques and meticulous manufacturing processes, these valves excel in providing precise and controlled fluid power, ensuring accurate measurement and testing outcomes.

Types of Test and Simulation Applications

Servo valves find their application in creating realistic environments within simulations and hydraulic test rigs. These servo hydraulic machines enable engineers to replicate complex scenarios, assess performance, and ensure the reliability of products and systems in various industries.

Some examples of test and simulation processes that rely on hydraulic systems include:

Automotive Testing

Crash Testing: Hydraulic systems are used to simulate vehicle crashes by controlling the movement of crash test dummies and other components.

Durability Testing: Hydraulic actuators apply repeated loads to test the durability of automotive components.

Aerospace Testing

Structural Testing: Hydraulic actuators simulate forces and vibrations to test the structural integrity of aerospace components and systems.

Materials Testing

Load Testing: Hydraulic systems are commonly employed to apply and control loads in structural testing scenarios to assess the static and dynamic properties of materials and structures.

Renewable Energy Testing

Wind Turbine Testing: Hydraulic systems are used to simulate wind forces and mechanical loads on wind turbine components during testing.

Oil and Gas Industry Testing

Pressure Testing: Hydraulic systems play a role in conducting pressure tests on pipelines, valves, and other components in the oil and gas industry.

Addressing Industry Challenges

Unstable loading

Conventional valves often face a lack of precision and consistency around fluid flow and pressure. This instability can cause issues such as equipment wear and tear, reduced operational efficiency, and an increased risk of system failures. Domin Servo valves address this concern and contribute to improved reliability and performance.

Slow response times

Standard valves exhibit slower response times, compromising efficiency and productivity in dynamic applications. Domin’s servo valves leverage cutting-edge technologies to ensure rapid response times and high bandwidth, facilitating high-speed testing and simulations.

Lack of dynamic control

Servo valves overcome the limitations of conventional valves by providing dynamic control in scenarios requiring precise adjustments to fluid flow and pressure. This enhances the overall performance of hydraulic test systems.

Energy waste

Mechanical feedback valves contribute to energy wastage due to inefficiencies in pressure and parasitic leakage. Domin’s servo valves precisely regulate flow rates and pressures, minimising energy consumption and fluid wastage for more sustainable operations.

Domin's Solutions: Precision, Speed, and Repeatable Results

Domin’s precision-engineered servo valves are optimised to deliver the high-flow, quick-response, and low-leakage performance needed for absolute control over hydraulic actuation, helping manufacturers uphold the highest standards of test and simulation performance. Whether controlling the position, force, or velocity of hydraulic actuators, Domin servo valves deliver exceptional resolution and set new standards for the precise control and replication of real-world scenarios.

Increased Accuracy

Domin’s servo valves boast very low hysteresis, ensuring accurate and repeatable movement of hydraulic actuators in both directions.

Seamless Upgrades

Selected servo valve as drop-in interchanges tailored to industry-standard frames facilitates seamless upgrades, enhancing system performance without extensive modifications. This reduces downtime and streamlines the upgrade process, ensuring cost-effectiveness and efficiency.

Reduced Energy Consumption

Domin’s servo valves minimise system losses, improve efficiency, and optimise energy usage by precisely controlling flow rates and pressures. Compared to a mechanical feedback valve, Domin’s servo valves have no pilot stage and therefore no parasitic leakage. This reduction in energy consumption helps manufacturers align with sustainability goals whilst lowering operational costs.

Extended Equipment Lifespan

Domin’s servo valves are much more resistant to contamination than traditional servo valves, meaning an increased number of cycles to failure, effectively extending the lifespan of your equipment. Experience reduced frequency of maintenance and replacements, ensuring a longer and more productive operational life.

Contact us to evaluate upgrading your hydraulic test stands with our high-performance servo valves tailored to your systems pressure and flow requirements. Explore what our customers have to say about their Domin valves in the testimonials section.