Ancient Beginnings

Hydraulic systems have played a crucial role in engineering throughout history by transforming how we harness the power of fluids to generate mechanical force and control. The use of hydraulics enables the movement of heavy loads and offers superior force compared to electrical, pneumatic, or mechanical alternatives. From ancient civilisations to the present day, the demand for increasingly efficient, reliable, and faster hydraulic systems has driven the development of some of the most revolutionary design and manufacturing methods that exist today.

Ancient Egypt serves as a very early example of fluid manipulation, initially used for industrial purposes. Settlements were strategically built around rivers to ensure easy access to water resources, and the river Nile played a vital role in the survival and prosperity of the Egyptian civailisation. They constructed a network of banks parallels to the river, leading into basins, a technique known as “basin irrigation”. Sluices were used to control the flow of flood water into these basins, saturating the soil to support crop growth. Excess water was drained off to nearby canals, facilitating the cultivation of various crops.

Moving forward in time, we encounter the development of the ancient Greek water clock, the clepsydra, around 325 BCE. The clepsydra revolutionised time measurement by employing the controlled flow of water. It was typically crafted from stone, taking the form of a bowl with a small hole at the bottom. As water flowed through this hole, it was collected in a second vessel positioned beneath it. Enhancements introduced by Ctesibius, an ancient Greek inventor, allowed for more accurate timekeeping. The rising water level indicated the passage of time, and each notch represented a new hour. The development of the water clock and its hydraulic principles laid the foundation for further advancements in hydraulic systems. It demonstrated the controlled manipulation of fluid to achieve specific outcomes.

Engineers during the Roman Empire made significant contributions to the evolution of hydraulics. They developed sophisticated water systems, including canals and aqueducts, to bring water to their villages and towns. In their pursuit of efficient water management, the Romans created the first hydraulic valves, resembling what we know today. These early valves were made of robust bronze and designed to be welded onto existing pipes. Their simplicity and practical design showcased the ingenuity of Roman engineers.

Advancements for Hydraulic Systems

The Renaissance period saw further advancements in hydraulics with inventions from visionaries like the Italian artist Leonardo DaVinci, the Flemish engineer Simon Stevin, and the French mathematician Blaise Pascal. Leonardo DaVinci’s sketches and designs offered innovative ideas and improvements, leading to significant advancements in hydraulic valve technology. This work inspired figures like Simon Stevin to investigate fluid statics, and Blaise Pascal to create Pascal’s Law, which said that when a fluid is at rest in a closed container, a pressure change in one part is transmitted without loss to every portion of the fluid and to the walls of the container. All these advancements pushed the boundaries of what could be achieved with hydraulics.

The Industrial Revolution marked a turning point in hydraulics with the invention of steam engine. The improvement of the valves within a steam engine to regulate steam at high pressures helped with the development of hydraulic technology dramatically. As the engineering evolved, hydraulic valves became essential components, driving advancements in their design and effectiveness.

Other key figures in hydraulic development during this period included Joseph Bramah, an English inventor and locksmith, who put Pascal’s Law in motion with his invention of the hydrostatic machine in 1795. And William George Armstrong, who discovered the “Armstrong Effect”, the physical process by which static electricity is produced by the friction of a fluid, and designer of a crane with reciprocating arm and the hydraulic accumulator.

Modern Hydraulic Systems

The 20th century brought further innovation with the addition of electrics and new pumping elements and mechanical feedback, making hydraulics suitable for vehicle power steering units. These improved the efficiency and effectiveness of hydraulic systems.

The demand for high-pressure fluid power components increased during World War I, particularly in the manufacturing of naval equipment. This demand led to the establishment of an entire industry dedicated to manufacturing high-pressure fluid power components, further advancing the field of hydraulics.

In 1950, William C. Moog Jr developed the first servo valve. This valve design revolutionised hydraulic control systems by providing precise and reliable control of fluid flow. Unlike traditional hydraulic valves, this servo valve utilised electrical input to modulate the flow of hydraulic fluid, offering better accuracy and responsiveness. This new technology allowed for specific positioning and control of hydraulic actuators in various applications, ranging from industrial machinery to automotive and aerospace systems. The Moog servo valve set a new standard for hydraulic performance and paved the way for the development of more advanced electrohydraulic systems.

However, since the 1950s, there has been minimal innovation to the design of the hydraulic valve. The main advancement in that time has been with the application of new software to improve systems. But with the compromise of existing hardware and basic electronics, the improvements in efficiency and performance have been incremental.

The Future of Hydraulics

At Domin, we have changed the way that hydraulic components are designed and manufactured. Our groundbreaking products offer a more sustainable, affordable, and exceptionally reliable alternative to the outdated technology that is currently available.

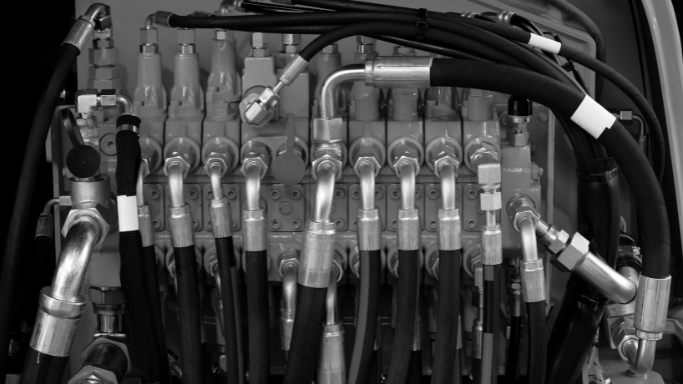

To achieve this, we use cutting-edge technologies such as additive manufacturing, modern onboard electronics, position sensing, and brushless DC motors to create small, compact, strong and fast components that will mark the next significant shift in the evolution of hydraulics. To learn more about our products and how you can bring your hydraulics systems into the 21st century, contact our Sales team.