Most hydraulic motion control systems use outdated technology that doesn’t take advantage of some of the technological advancements of the past few decades. At Domin, we have taken a pioneering approach to creating our hydraulics technology, taking advantage of cutting-edge technologies to create highly efficient, performant, and reliable hydraulics systems.

In this article, we have a look at some of our core tools and how we use them to create our groundbreaking hydraulic technology.

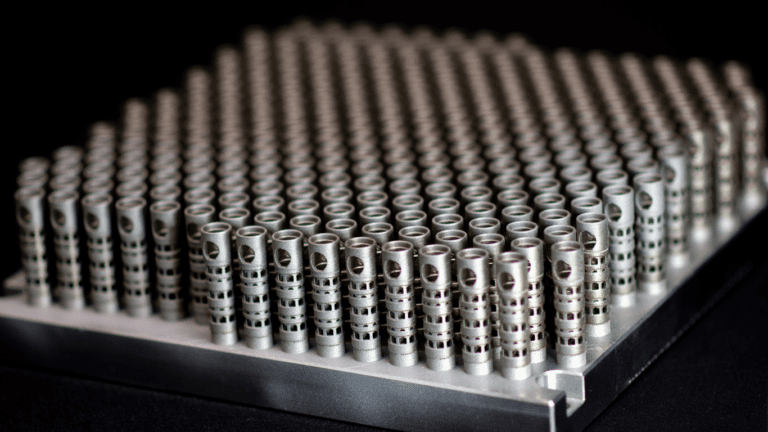

Metal Additive Manufacturing

Additive manufacturing, also known as 3D printing is a manufacturing process in which components are built up layer by layer. Additive manufacturing using thermoplastics has gained widespread popularity in recent years, but metal additive manufacturing has seen limited use in mass-produced products. We are one of only a handful of companies that use the technology to fully produce commercial products.

Additive manufacturing has allowed us to realise a complete redesign of what servo valves and hydraulic systems can be. We use additive manufacturing to create complex internal geometries that optimise fluid dynamics to enhance the efficiency and performance of our servo valves. By having full control over how components are produced, we can eliminate unnecessary material, and better determine how the material is distributed. This results in lower-cost, lightweight components that are relatively cheap and efficient to produce.

The nature of additive manufacturing makes it fairly simple to take a modification from the design stage through to the actual manufactured part. This allows us to customise our designs and the characteristics of our systems to specific requirements.

Modern Electronics

We use modern electronics to optimise the performance and reliability of servo valves. Advanced digital signal processing algorithms are used to enable real-time monitoring and adjustment of control signals to improve the performance of our valves. Modern communication interfaces allow integration with external systems or controllers, enabling remote monitoring and diagnostics, and data exchange, to ensure our valves and hydraulic systems run optimally.

Our electronics allow us to monitor relevant parameters to detect anomalies, with self-diagnostic features allowing for real-time fault detection. Our systems are configurable and programmable, allowing their behaviours to be customised and adding unparalleled flexibility to our customers’ systems.

Brushless DC Motors

Brushless DC motors forego brushes and commutators that are typically used in traditional DC motors. Although the technology has been around for a while, Domin has pioneered its use in hydraulic motion control systems. Brushless DC motors allow for precise control over position and speed, with a smooth motion that makes it ideal for industrial automation and automotive applications. Additionally, brushless DC motors do not have the problem of brushes wearing out over time, extending their life span while keeping maintenance requirements low.

Magnetic Position Sensors

Magnetic position sensors use magnetic fields to measure the position and movement of the rotor in our servo valves. This removes the wear and tear that is present in traditional servo valves between the spool and the sensing element, which extends the life span of the sensor and reduces the risk of malfunction from vibrations or contaminants.

Magnetic position sensing is extremely accurate, with a high resolution of measurements. This enables us to have extremely precise control over the position of the spool in our servo valves. Additionally, magnetic position sensing has extremely fast response times, reporting the position of the spool in real-time, and allowing the system to make adjustments at speeds previously unattainable with traditional designs. Lastly, magnetic position sensing is very stable, maintaining accuracy over long periods. This is just one more design feature that adds to the reliability of our systems.

How We Use These Tools to Create Redefining Hydraulic Technology

We use these cutting-edge tools and techniques to create the world’s most compact and powerful high-speed valves. This ground-breaking valve technology is found in our high-performance servo valves, as well as our hydraulics systems and subsystems, from our brake-by-wire solutions to active suspension, and advanced flight-control actuators.

We’ve also used these tools to design a radial piston pump for use in hydraulic systems that is lightweight, with high power density and high torque.

Defining a New Age for Motion Control

Our focus on lightweight, highly efficient hydraulic motion control technology leads to massive improvements in energy efficiency, which has a direct cost effect while improving the overall sustainability of systems. For example, our flight-control actuation systems can lead to a 50% weight reduction of current systems, which is a massive enabler for future aerospace design.

On top of these advances, our systems offer world-leading performance and reliability, paving the way for further innovation in the aerospace, automotive, and industrial manufacturing industries.