In the realm of fluid mechanics, few principles have had as profound an influence on engineering and technology as Pascal’s Principle. Named after the French mathematician and physicist that discovered it, it is the fundamental concept that lies at the heart of hydraulics – a field that has revolutionised important industries ranging from construction to aviation.

In this article, we will delve into Pascal’s Principle and explore its pivotal role in the evolution of hydraulics, how hydraulics has reshaped the modern world and continues to drive innovation across a multitude of industries.

What is hydraulics?

Hydraulics is a branch of science and engineering that revolves around understanding how fluids behave and how they can be used to transmit force. It is a component of mechatronics, which combines mechanical, electrical and software engineering to design and manufacture processes and products.

Typically, a hydraulic system consists of several key components, including a fluid reservoir, a pump providing hydraulic power, a number of control valves, hydraulic cylinders or motors, and an interconnected network of fluid lines.

The executing parts of the system are the hydraulic cylinders. These cylinders are made up of cylindrical chambers which are sealed against each other by the moveable piston. Most cylinders also have fluid ports at each chamber.

When the hydraulic system is activated, fluid is pressurised through the pump and resistances in the system. Precise control in hydraulic systems comes from adjusting the flow of hydraulic fluid in and out of the cylinder chambers. This is done through valves and control mechanisms. By regulating the flow rate and direction of the fluid, operators can direct the piston’s movement, allowing them to control the resulting mechanical motion accurately.

The mechanical movement produced by actuators can take various forms, depending on the system’s design and purpose. When the system uses cylinders, the mechanical movement will be linear, like in hydraulic lifts and excavator arms. The movement can also be rotational when hydraulic motors are used. One of the key advantages of hydraulic systems is their high power density. They are capable of transmitting significant force and motion for challenging applications. Their reputation for durability and reliability has led to their adoption in a number of important industries.

Hydraulics are everywhere. They are essential in construction equipment, such as hydraulic excavators and bulldozers, as well as in manufacturing processes, including hydraulic presses, jacks, and hydraulic lifts. In aerospace, hydraulic systems for applications like aircraft landing gear, while the automotive industry relies on hydraulics for components like brakes and power steering.

What is Pascal’s Principle?

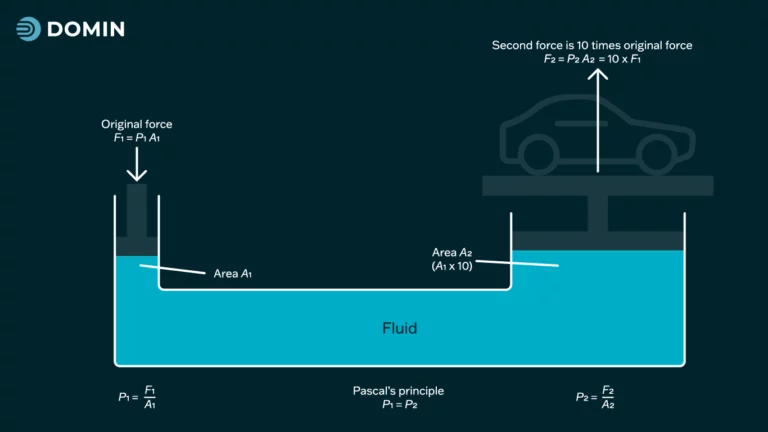

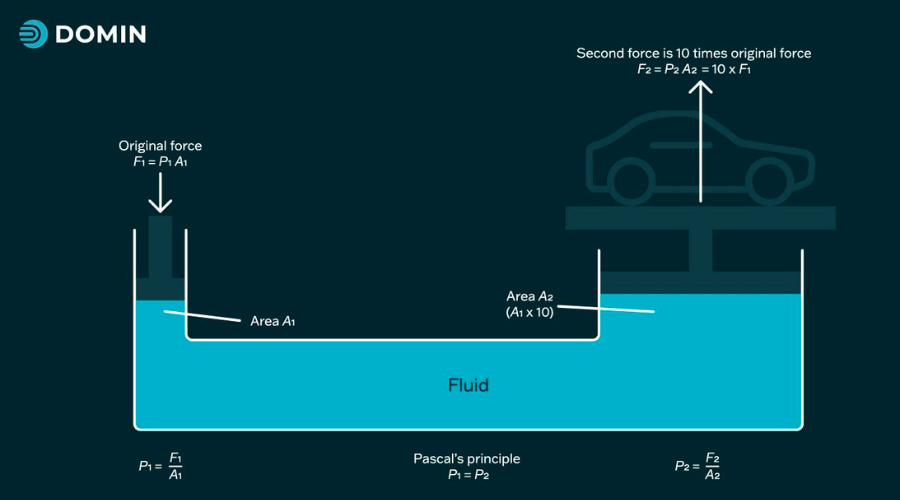

Pascal’s Principle, otherwise known as Pascal’s Law or Pascal’s Formula, was established by French mathematician Blaise Pascal in 1653 and published in 1663. The law states that when there is an increase in pressure at any point in an incompressible contained fluid, there is an equal increase at every other point in the container. It declares that, while the pressure in a confined fluid is always equal, the force exerted depends on the surface area.

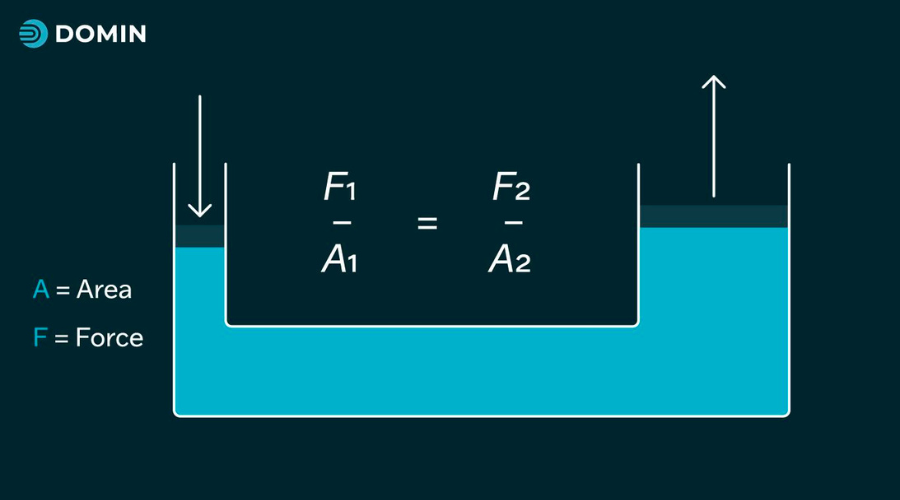

A= Area F= Force P = Pressure

As you can see in the above graphic, the force applied to the first section of the cylinder (F1), divided by the surface area of that section (A1), is equal to the force exerted at the second section of the cylinder (F2), divided by the surface area of that section (A2). If the surface area of each section is the same, the force will be the same. However, if the cross-sections are different, you have to apply Pascal’s formula to find the force exerted at section 2

F1/A1 = F2/A2

P1 = F1/A1

P2 = P1

If F1 = 100 and A1 = 10, F2= F2 and A2 = 20

100 / 10 = F2/20

P1 = 100 / 10 = 10

F2/ 20 = 10

F2 = 200

Applications of Pascal’s Principle in hydraulics

One of the most practical applications of Pascal’s Law can be found in hydraulic systems. According to Pascal’s formula, in a hydraulic system, when pressure is applied to one piston, it results in an equivalent pressure rise on another piston within the system.

This means that transmission of the pressure results in amplification of the force in a piston with a larger cross-section.

This amplification of force is what makes hydraulic systems so valuable in industries like construction, automotive engineering, and manufacturing. They facilitate meticulous control and optimal exploitation of hydraulic power by means of fluid pressure modulation. The enduring significance of Pascal’s Law in engineering remains paramount, continually contributing to technological advancements that enhance our modern way of life.

The exploration of Pascal’s Principle and its profound connection to the field of hydraulics unveils a world of innovation and practical applications that have reshaped the way we live and work. From the humble beginnings of Blaise Pascal’s observations on fluid behaviour, this principle has become a cornerstone of modern engineering, enabling us to accomplish tasks that were once considered impossible.

The simplicity of Pascal’s Principle continues to create opportunities for progress and innovation. From the hydraulic systems that power our everyday lives to the complex machinery that propels us into the future, the exploitation of Pascal’s Law by hydraulic systems and machines has not only enhanced our modern way of life but also serves as a testament to the enduring power of scientific principles in shaping the world around us. As technology advances and our understanding of fluid dynamics deepens, we can look forward to even greater achievements on the horizon, all built upon the timeless foundation laid down by Pascal and his groundbreaking principle.

How Domin can help

At Domin, we’ve embarked on a transformative journey in the design and production of hydraulic systems.

Oak Ridge National Laboratory estimated that most hydraulic systems only operate at 23% efficiency, resulting in billions of kWh of energy being wasted annually. At Domin, we recognise that this needs to change, and so, through advanced engineering processes, architectural design, and using additive manufacturing, modern electronics, brushless DC motors, and sensing equipment, we have gone back to the drawing board and designed revolutionary hydraulic valves and systems that are digitally signalled, allowing us to better build efficient systems.

Our pioneering products represent a sustainable, cost-effective, and dependable departure from traditional hydraulic solutions currently in use across the aerospace, automotive and industrial sectors, marking a remarkable milestone in the evolution of hydraulics. To explore more of our groundbreaking hydraulic systems, contact our Sales team.

Together, we can bring your hydraulic systems firmly into the 21st century.