Our approach to innovation stems from a desire to challenge the status quo. By pushing the boundaries of conventional systems and embracing cutting-edge technologies, we have created something new. This relentless pursuit of efficiency and performance optimisation in hydraulics will create cutting-edge solutions that surpass the limitations of existing hydraulic systems.

But to create something new, we need to fully understand the foundations. We’ve already spoken about Pascal’s Principle of Hydraulics and the components of a hydraulic system, so in this article we are going to explore the aims of a hydraulic system.

What are Hydraulic Systems?

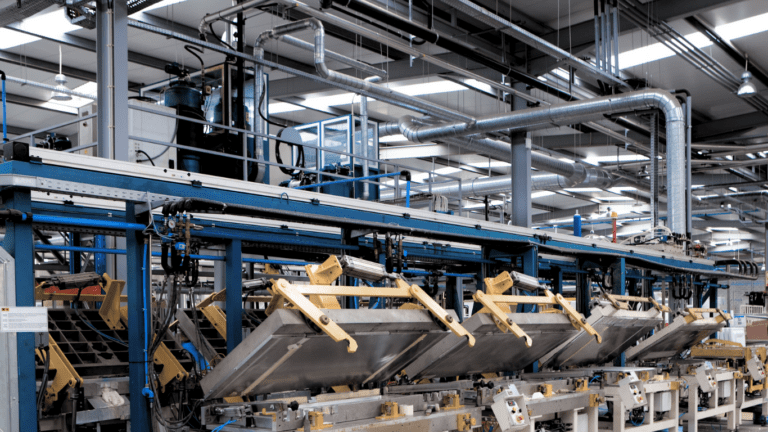

A hydraulic system uses fluid to transmit power and movement of various components in a mechanical system. The fundamental components of a hydraulic system include a pump, valves, actuators and hydraulic fluid. These systems are widely used in a variety of applications across industries due to their ability to efficiently transmit force, provide precise control, and operate under various conditions.

The Purpose of a Hydraulic System

Hydraulic systems have several different purposes that are used in various different engineering applications.

Transmitting Force and Motion

Hydraulic systems excel at transmitting force, making tough jobs more manageable. They transmit force and motion through the use of hydraulic fluids. Hydraulic systems amplify a small input force into a significantly larger force, which is an important feature for heavy-duty tasks like lifting heavy objects in construction, controlling high performance vehicles, or bending metals in metalworking.

In essence, hydraulic systems are all about efficiently getting force from one place to another, allowing us to handle heavy tasks with accuracy and dependability. Traditionally, the input would have been humans moving small levers to amplify the circuit. With the introduction of advanced electronics, electrical signals control the movement – which can be as simple as someone pushing a button or as complicated as fully autonomous systems

Precise Control and Accuracy

Hydraulic systems also aim to provide precise control of motion, ensuring the user can accurately adjust the speed, direction, and force of the product by using hydraulic valves, regulators and sensing. The inherent features of hydraulic fluid guarantee instantaneous transfer of energy to enable smooth, controllable motion, making them suitable for aerospace, automotive and other extremely demanding industries.

With modern electronics and IoT connectivity, hydraulic systems can be operated remotely, making hydraulic systems the safest option in hazardous and hard-to-access environments, or the most efficient option to support the electrification of all industries.

Energy Efficiency

Hydraulic systems can achieve efficiency by quickly controlling when and how power (pressure and flow) is used in the system to ensure only the required amount of power is being used during the duty cycle. Most hydraulic systems output continuous flow and pressure, from hydraulic pumps (variable displacement pumps or variable speed control), and throttle flow to control the output. This results in very high energy consumption. When a hydraulic system controls flow only when motion is required, the energy consumption can be managed far more effectively.

Some systems also possess regenerative features that recover and reuse energy during deceleration, further improving overall efficiency.

Reliability and Maintenance

Reliability is an important feature to maintain performance and profitability. Downtime from faulty valves and maintenance costs industrial manufacturers millions of dollars each year. Dust, debris, and moisture can infiltrate open-loop hydraulic systems, which can cause important components to become jammed or worn down more quickly.

The sealed design of closed-circuit hydraulic systems keeps the hydraulic fluid in a controlled environment and reduces the risk of contamination. Closed-circuit hydraulic systems are less likely to become contaminated, enhancing their reliability, leading to longer component life, reduced maintenance requirements, and a more consistent system performance.

Versatility and Adaptability

Another important aim of hydraulic systems is to be adaptable and customisable for different requirements and applications. This adaptability includes adjusting the size and capacity of hydraulic components, such as pumps, cylinders, and valves, to ensure optimal performance.

The energy efficiency of hydraulic systems is also highly adaptable, depending on what your requirements are. By optimising the design and components, hydraulic systems can be tailored to minimise energy consumption while achieving the desired level of performance.

How Domin can Help

Hydraulic systems aim to efficiently transmit force and motion, provide precise control, minimise energy consumption, and ensure reliability and adaptability without compromise to performance.

Our state-of-the-art distributed, electrically controlled systems can increase overall system efficiency. Our reputation for durability and adaptability ensures that we deliver for our customers in industries where hydraulic systems play a vital role in achieving innovation and operational efficiency. To understand how our pioneering hydraulic products can help you improve the efficiencies of your systems, contact our Sales team.