The first servo valve was invented in 1950 and are an essential component of any hydraulic system. High performing and reliable servo valves are required to ensure precise control and accurate movement of machinery. Over the years, servo valves have been applied to a wide variety of applications across the globe including aerospace, industrial automation, injection moulding, offshore systems, and testing and simulation machines.

Aerospace

Hydraulics play a crucial role in various aircraft systems, including flight control systems, brake systems, and landing gear. They provide the necessary power and accuracy to control the aircraft’s movement, ensure safe landings, and enable effective ground operations.

Flight controls

Hydraulic systems are used to control various flight control surfaces, such as ailerons, elevators, and rudders. Valves help in translating the pilot’s input into precise movements of these control surfaces. The responsiveness of servo valves in this application are critical for achieving accurate control over the aircraft’s movements.

Brake systems

Hydraulic systems are also used to ensure the smooth operation of brakes during landing and ground operations. For brake actuators, valves ensure that the appropriate amount of pressure is applied to the brake system, allowing for controlled deceleration during landing rollouts.

Most modern aircraft brake systems incorporate antiskid systems to prevent skidding and improve braking efficiency. These systems use valves to modulate hydraulic pressure to individual brakes to prevent wheel lockup during braking, especially on slippery surfaces.

Landing Gear

Hydraulic actuators extend and retract the landing gear during take-off and landing. These actuators are powered by hydraulic pressure and controlled by valves.

Landing gear systems include shock absorbers that use hydraulics to dampen the impact forces during landing. Hydraulic fluid flows through the shock absorbers, absorbing and dissipating energy.

Aircraft often have hydraulic backup systems too for emergency landing gear extension. These systems use hydraulics to manually or mechanically extend the landing gear in case of hydraulic system failures.

Industrial Automation

Robotics

Servo valves are used to enable accurate and coordinated movements of robotic arms and grippers. They allow for accurate control of joint angles, speeds, and forces, enabling robots to perform intricate tasks with exceptional accuracy.

Assembly Lines

In assembly lines, servo valves enable precise control of part positioning, joining, and fastening. They ensure that components are accurately aligned and securely connected, minimising errors and improving product quality. The ability to synchronise multiple hydraulic actuators with precision allows for seamless coordination of assembly line operations, resulting in higher throughput and reduced cycle times.

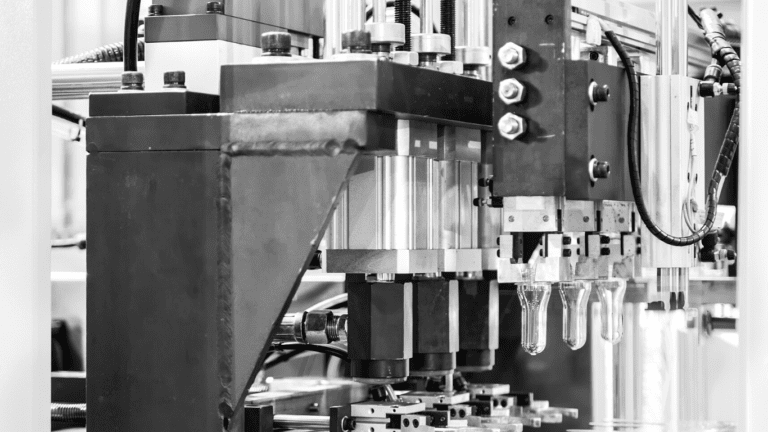

Machine tools

Lathes, milling machines, and presses also require servo valves. In this application, the valves control the movements of tool heads, slides, and workpiece clamps to enable accurate machining, shaping, and forming operations. With precise control over forces and speeds, servo valves enable high-precision cuts, smooth surface finishes, and reliable repeatability, contributing to improved machining accuracy and quality.

Injection Moulding

Servo valves are commonly used in injection moulding machines, which is widely used in the plastic manufacturing industry. For this application, valves are used to ensure control of the mould clamping force, injection speed, and material flow, ensuring high-quality and consistent production of plastic parts.

Mould Clamping Force

By accurately regulating the hydraulic pressure applied to the mould, servo valves ensure that the mould remains securely closed during the injection process. This precise control prevents flash, warping, or other defects in the final moulded parts, resulting in improved part quality and dimensional accuracy.

Injection speed control

Injection speed control is another vital aspect of injection moulding, and hydraulic servo valves excel in this area. The valves enable exact adjustment of the hydraulic fluid flow rate, enabling controlled and consistent injection of molten plastic into the mould cavity. By maintaining optimal injection speeds, a servo valve can ensure uniform filling, minimising the occurrence of flow marks, voids, or uneven material distribution within the moulded parts.

Material Flow

To achieve accurate regulation of material flow during the injection process, servo valves are used to control the speed and pressure of the cylinder that is used to control the feed screw that pushes the plastic into the mould. This ensures proper filling of the mould cavity and precise replication of intricate details. This level of control is especially critical for complex parts with fine features, ensuring that every detail is accurately reproduced, resulting in high-quality finished products.

Marine and Offshore Systems

Ship steering

Servo valves are used to control the movement of rudders, ensuring accurate and responsive steering. The valves themselves enable adjustments of hydraulic pressures to control the angle and position of the rudder as the captain steers. Not only does this allow for accurate course corrections and manoeuvrability, but it also allows us to build bigger ships as extreme load can be applied to the pressure by a small movement.

Winches

Winches are commonly used for maritime operations such as towing, anchoring, and lifting. They heavily depend on servo valves to regulate the hydraulic pressure and flow to control the speed, torque, and tension of winch operations. With the assistance of servo valves, operators can precisely control the payout and retraction of cables or ropes, ensuring controlled and safe handling of loads and equipment.

Propulsion system

Propulsion systems such as marine engines and thrusters use servo valves to govern the pitch, angle, and rotational speed of propellers or water jets. By accurately adjusting the hydraulic flow and pressure, servo valves can allow for optimal power transmission and thrust control, enhancing vessel maneuverability, speed, and fuel efficiency.

Test and Simulation

Automotive component testing

When it comes to automotive, servo valves are used to test suspension systems, braking systems, and steering systems. By accurately replicating real-world operating conditions, the valves allow engineers and researchers to assess the performance, durability, and safety of automotive components under controlled and realistic circumstances.

Aircraft flight simulators

Servo valves are also used to provide realistic and immersive training environments for pilots and aviation professionals. They are used in test systems that simulate the movements and responses of various aircraft control surfaces. By accurately replicating the hydraulic systems’ behaviour, servo valves allow pilots to experience and practice different flight scenarios, enabling them to develop and enhance their skills in a realistic flight environment.

Industrial process simulations

Servo valves are used to replicate hydraulic systems found in manufacturing processes and industrial equipment. These simulations are used to evaluate the performance, efficiency, and reliability of hydraulic systems before their implementation. By accurately controlling the hydraulic parameters, such as pressure, flow, and actuator movements, servo valves enable engineers and operators to assess the behaviour of the system under different operating conditions. This allows for optimisation of processes, identification of potential issues, and validation of design concepts, ensuring the reliable and efficient operation of industrial equipment.

The diverse application of servo valves allows industries to harness their capabilities and optimise operations in their respective fields. At Domin, our valves can be used for all the above applications and are the highest performing and most reliable valves currently available on the market.

We offer direct replacements for a wide range of competitor valves and our knowledgeable Sales team can assist you in finding the best option for your specific requirements. Get in touch for more information.

Explore some of our